In the consumer packaged goods (CPG) personal care industry, businesses rely on advanced modeling techniques to stay ahead of the competition, streamline supply chains, and meet consumer expectations. Two powerful approaches to modeling supply chain and operational dynamics are Agent-Based Modeling (ABM) and Equation-Based Modeling (EBM). While both approaches are invaluable, they serve distinct purposes and offer different insights. Here are the differences between, and practical applications of, ABM and EBM in the CPG personal care industry.

Agent-Based Modeling (ABM): Simulating Individual and Dynamic Behaviors

Agent-based modeling (ABM) is a bottom-up approach that simulates the actions and interactions of individual entities – or agents – to understand their impact on the overall system. These agents can represent consumers, suppliers, manufacturers, and retailers, each with unique behaviors and decision-making processes. ABM’s strength lies in capturing the complexity of decentralized systems and revealing emergent phenomena that would be hard to predict otherwise.

Applications of ABM in CPG Personal Care

- Demand Forecasting and Consumer Behavior Simulation: ABM can simulate how individual consumers select various personal care products, such as shampoos, lotions, or deodorants. By modeling consumer preferences, brand loyalty, and responses to promotions, companies can refine marketing strategies and better anticipate demand fluctuations.

- Supply Chain Resilience: By representing suppliers, contract manufacturers, and retailers as agents, ABM helps businesses simulate the impact of disruptions, such as geopolitical tensions or natural disasters. For instance, ABM can evaluate how a delay in receiving surfactants or HDPE bottles from a supplier affects inventory levels and downstream production.

- Product Innovation and Market Response: ABM is useful for understanding how consumers adopt innovations like eco-friendly packaging or new formulations (e.g., sulfate-free shampoos) and demonstrating how these changes spread through the market and affect competition.

- Bullwhip Effect Analysis: ABM reveals how small changes in retail demand amplify as they move upstream in the supply chain, leading to inefficiencies like overproduction or stockouts. It also identifies optimal reorder points and inventory strategies to mitigate such issues.

Equation-Based Modeling (EBM): Understanding Aggregate System Dynamics

Equation-based modeling (EBM) takes a top-down approach, using mathematical equations to represent relationships between variables. This method focuses on overall system performance, offering a high-level view of supply chain dynamics. EBM is particularly effective for analyzing steady-state conditions and optimizing resource allocation.

Applications of EBM in CPG Personal Care:

- Production Optimization: EBM uses equations to model production rates, inventory levels, and machine utilization, ensuring efficient operations. For example, EBM can help optimize production schedules for lotions and body washes to minimize downtime.

- Inventory Management: Using reorder point and safety stock formulas, EBM helps companies manage inventory levels for seasonal products, such as sunscreen, thereby reducing carrying costs while improving service levels.

- Supply Chain Cost Modeling: EBM quantifies transportation, raw material, and warehousing costs, and can calculate, for instance, the total landed cost of sourcing packaging materials from different regions, such as injection-molded caps.

- Sustainability Metrics Tracking: EBM links production volume, energy consumption, and transportation distances to environmental metrics, such as carbon emissions. This supports sustainability initiatives while maintaining cost efficiency.

- Shelf Life and Expiry Modeling: Equations predict the degradation of active ingredients under various conditions, such as retinol in lotions, ensuring accurate expiration dates and waste reduction.

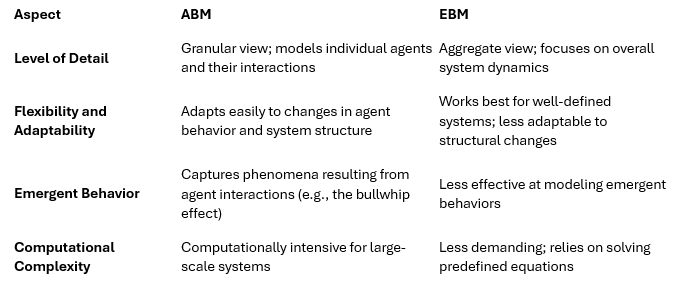

Comparing ABM and EBM in CPG Personal Care:

Real-World Applications in CPG Personal Care

- ABM Example: A personal care brand launches a new eco-friendly shampoo. ABM simulates how consumers adopt the product, how competitors react, and how supply chain partners adjust to increased demand for sustainable packaging materials.

- EBM Example: A company uses equations to model the transportation costs of sourcing HDPE bottles from suppliers in Asia, comparing costs with local suppliers in Mexico, to determine the most cost-effective strategy.

The Future of Modeling in CPG Personal Care

As the CPG personal care industry pursues improved resilience and sustainability, the leveraging of both ABM and ENM modeling becomes invaluable for achieving operational excellence. By integrating the more granular insights of ABM with the high-level analytics of EBM, businesses can enhance their ability to innovate, adapt, and thrive in a competitive market.

Integrating ABM and EBM for Comprehensive Insights: A Hybrid Approach

We live in a VUCA world, and adapting to continually changing, often disrupted, market dynamics requires more than choosing a single modeling technique. Agent-based modeling provides detailed insights into individual behaviors, while equation-based modeling delivers system-level analyses. When these two powerful modeling methodologies are combined to form a hybrid approach, unprecedented opportunities to tackle challenges that neither ABM nor EBM can address alone are uncovered.

Why Integrate ABM and EBM?

In isolation, ABM excels at simulating consumer behavior, supply chain disruptions, and innovation adoption, while EBM focuses on system-level optimization, cost analysis, and resource allocation. However, many real-world problems require granular insights and aggregate perspectives. Hybrid modeling bridges this gap, creating a dynamic synergy that can:

- Enhance Decision Making: Combine individual agent behaviors with overarching system dynamics to make more informed strategic decisions.

- Improve Forecasting Accuracy: Layer granular consumer demand simulations onto high-level production and distribution models.

- Strengthen Resilience: Analyze how individual disruptions cascade through the supply chain and impact system-level performance.

Applications for Hybrid Modeling in CPG Personal Care

- Product Launch Planning:

- ABM Layer: Simulate consumer adoption rates and competitor reactions to a new sulfate-free shampoo.

- EBM Layer: Optimize production schedules and inventory management based on predicted adoption rates.

- Hybrid Output: Develop a unified plan that aligns production capacity with anticipated demand spikes and regional preferences.

- Supply Chain Disruption Management:

- ABM Layer: Model supplier and distributor responses to raw material shortages.

- EBM Layer: Quantify overall impacts on transportation costs, lead times, and service levels.

- Hybrid Output: Outline a mitigation strategy that evaluates both immediate responses and long-term adjustments.

- Sustainability Initiatives:

- ABM Layer: Simulate consumer preferences for eco-friendly packaging and their effect on purchasing habits.

- EBM Layer: Calculate environmental metrics, such as carbon emissions and energy use, for alternative supply chain setups.

- Hybrid Output: Create an actionable plan that balances consumer satisfaction with sustainability goals.

- Dynamic Pricing Strategies:

- ABM Layer: Assess consumer sensitivity to pricing changes for seasonal products.

- EBM Layer: Model revenue and profit margins under different pricing scenarios.

- Hybrid Output: Develop a dynamic pricing model that maximizes revenue while maintaining market competitiveness.

Steps for Implementing Hybrid Modeling in the CPG Personal Care Industry

- Define Objectives: Start by identifying the specific business challenges that need to be addressed, such as optimizing a new product launch or improving supply chain resilience.

- Develop Parallel Models: Build separate ABM and EBM frameworks tailored to the challenge at hand.

- Integrate and Calibrate: Combine insights from both models and validate results using historical data or pilot projects.

- Test Scenarios: Run simulations to explore the interplay between individual and system-level dynamics under diverse conditions.

- Iterate and Refine: Use real-world data to continuously update and refine the hybrid model for improved accuracy.

Choosing the Right Model for Your Needs

Both ABM and EBM offer unique advantages for the CPG personal care industry. ABM excels in capturing the nuances of agent interactions and adapting to dynamic changes, making it ideal for complex and decentralized systems. EBM, on the other hand, provides a streamlined, high-level view that is perfect for optimizing established processes and tracking key performance metrics.

By employing these models in tandem, businesses can achieve a comprehensive understanding of their supply chains, enabling smarter decisions, greater resilience, and enhanced customer satisfaction.

This hybrid approach is not just the future of modeling; it’s the key to staying ahead in a world where both precision and perspective matter. We are end-to-end Supply Chain and Procurement Consultants and Advisors. Ask how we can grow your top and bottom line through an efficient supply chain. Learn more about our services and book a discovery call.