Antifragile supply chains are the next evolution in supply chain excellence.

Last month, I wrote about the importance of building resiliency into your supply chain.

A lack of resilience and responsiveness in the wake of unforeseen circumstances can put your business at risk of hemorrhaging money. Yet, supply chain disruption is sometimes unavoidable; breakdowns occur. But we can plan for zero risk.

With one of my clients, we faced a situation that, by all accounts, was very low risk. The supplier of a critical component experienced a rare equipment failure that had a very low probability of happening. Nevertheless, the impact was significant. Our strategy immediately turned to one of containment. Containing the losses to the lowest dollar with minimal customer impact became our rallying cry. This is where experience, technical knowledge, and supplier relationships come into play.

Bringing together a team and including several suppliers to help solve the issue, we turned over every stone and contained the damage. We made some short-term tactical decisions to stop the bleeding and put a long-term solution in place that had plenty of redundancies to minimize impactful risks. What could have been three months of downtime had been contained to one month.

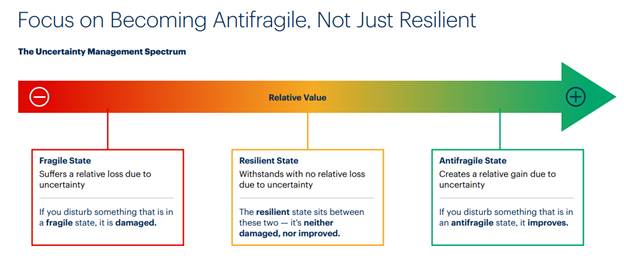

In an era when supply chain disruptions are more the rule than the exception, resilience is no longer optional. It’s imperative. But building resiliency is only the start. The end goal is to move beyond resiliency and into the next generation of productivity: antifragile supply chains.

This is something Gartner discusses in their report, Chief Supply Chain Officer Leadership Vision 2024: 3 Strategic Actions for Success. Embracing the concept of becoming antifragile requires a significant mind shift, because most companies are, at best, striving only for resiliency. Even so, most of them are still somewhat fragile, where, if something disturbs the supply chain, damage results. Gartner’s charge to supply chain officers is to focus on becoming antifragile.

So, What Is an Antifragile Supply Chain?

An antifragile supply chain is a system designed not just to withstand shocks and disruptions but to grow stronger as a result. In an antifragile supply chain, leaders embrace the idea that disruption is part of the process; they internalize disruption as part of the planning process, not something that interrupts it.

The concept of antifragility, introduced by Nassim Nicholas Taleb in his book, Antifragile: Things That Gain from Disorder, describes systems that benefit from stressors, volatility, and uncertainty.

What Does an Antifragility Look Like?

Gartner recently released their Supply Chain Top 25 for 2024. With respect to these top 25, Gartner writes that “[these companies] don’t just push products; they understand customer value, invest in demand management and promote innovation against ESG.” These companies exemplify the effort required to achieve supply chain excellence, and Gartner identifies antifragile supply chains as one of the ways these 25 companies stand apart:

To move a supply chain into the antifragile state requires a number of shifts that influence how decision-making processes, technology, network design and many other elements of strategy are conceived and used. Using the preceding macro trend as an example of the shift needed, AI-driven advances could make your supply chain either more or less fragile depending on the paradigm. The Top 25 leaders don’t try to get a false sense of certainty through the use of AI tools, but instead use them to expose and understand the impact of uncertainty on supply chain performance and act based on that understanding.

Honored apart from the top supply chain leaders are four “Masters” of supply chain excellence: Amazon, Apple, P&G, and Unilever. I am very fortunate to be a “graduate” of Unilever, one of the Masters. Training at Unilever is like earning a PhD in supply chain.

Characteristics of an Antifragile Supply Chain

- Adaptability: An antifragile supply chain can quickly adapt to changes in demand, supply disruptions, or other unexpected events. This includes having flexible manufacturing processes, diversified supplier bases, and dynamic inventory management strategies.

- Redundancy and Diversity: An antifragile supply chain doesn’t rely on a single source for critical components or raw materials. Instead, it has multiple suppliers and diverse procurement strategies to mitigate risks.

- Decentralization: Instead of centralizing operations, an antifragile supply chain decentralizes its functions. This reduces the impact of localized disruptions and allows different parts of the supply chain to respond independently and more effectively to changes.

- Continuous Improvement: Such a supply chain constantly evolves through feedback loops. It learns from past disruptions and failures, implementing improvements that make it more resilient over time.

- Agility: An antifragile supply chain can respond swiftly to changes in the market environment. This agility often involves leveraging advanced technologies, such as AI and IoT, for real-time data analysis and decision making.

- Innovation: Antifragile supply chains encourage experimentation and innovation, learning from both successes and failures. These might include exploring new technologies, business models, or processes that enhance overall robustness.

But How Do I Get to the Point Where I Actually Have an Antifragile Supply Chain?

Building an antifragile supply chain requires a shift in mindset and the adoption of key principles. Here are some fundamental principles to consider:

- Embrace uncertainty: Instead of trying to eliminate uncertainty, view it as an inherent part of the business environment. Anticipate and prepare for disruptions, rather than being caught off guard.

- Diversify your network and create redundancies: Relying on a single supplier or a limited set of suppliers can increase vulnerability. Build a diverse network of suppliers and develop alternative sourcing options to mitigate risks.

- Foster collaboration and transparency: Encourage open communication and collaboration across all stakeholders within the supply chain. Share information, insights, and best practices, to enable faster problem solving and decision making.

- Invest in advanced technologies: Leverage technologies, such as cloud computing, IoT, and predictive analytics, to improve visibility, automate processes, and enable real-time decision making.

- Continuously learn and adapt: Treat disruptions as learning opportunities and use them to improve processes, identify weaknesses, and implement necessary changes. Foster a culture of continuous improvement and innovation.

Tools and Technologies that Support Antifragile Supply Chains

Implementing an antifragile supply chain requires the right tools and technologies to support your operations. These key technologies can enhance the resiliency and adaptability of supply chains:

- Cloud computing: Cloud-based platforms provide scalability, flexibility, and real-time access to data, enabling better coordination and collaboration across the supply chain.

- IoT: IoT devices can collect real-time data from various points in the supply chain, enabling enhanced visibility and proactive decision making.

- Predictive analytics: By analyzing historical and real-time data, predictive analytics can help identify patterns, forecast demand, and anticipate potential disruptions.

- Blockchain: Blockchain technology can promote transparency, traceability, and trust within the supply chain. It enables secure and immutable recordkeeping, reducing the risk of fraud and ensuring compliance.

- AI: AI can revolutionize your supply chain. AI-powered algorithms can analyze vast amounts of data, identify patterns, and recommend optimal actions. It goes without saying that AI can automate routine tasks, improve forecasting accuracy, and enable autonomous decision making.

Implementing Antifragile Supply Chains

Becoming more antifragile starts with:

- Assessing and evaluating the strengths and weaknesses of your existing supply chain. Identify areas that are vulnerable to disruptions and areas where improvements can be made.

- Defining your antifragile supply chain strategy and developing a clear vision for your antifragile supply chain. Define the goals, objectives, and key performance indicators that will guide your efforts.

- Identifying potential disruptions and conducting a thorough analysis of potential risks that could impact your supply chain. Develop contingency plans and risk mitigation strategies to minimize their impact.

- Shifting your mindset about the role of procurement. Procurement is no longer just about cost savings and supply chain efficiency. It’s about strategic value creation, innovation, and resilience. And it’s also about generating cash savings. However, procurement professionals are not typically trained to think this way. Procurement pros must look up and down the value chain to find opportunities for liberating cash by working with suppliers to reduce working capital.

- Building a network of trusted partners and establishing relationships with suppliers, logistics partners, and other stakeholders based on trust, transparency, and shared values. Collaborate to enhance visibility and responsiveness across the supply chain.

- Investing in advanced technologies that align with your antifragile supply chain strategy and invest in their implementation. Ensure proper integration and data management to leverage the full potential of these technologies.

- Monitoring and continuously improving the performance of your antifragile supply chain and gathering feedback from stakeholders. Identify areas for improvement and implement necessary changes to enhance resilience and productivity.

You can’t just snap your fingers and suddenly become antifragile. It’s a process, one that starts with understanding your current supply chain strengths and weaknesses. As you evaluate your supply chain and uncover the vulnerabilities in your current process, you can begin identifying the areas of your supply chain that are most at risk. If we had another pandemic tomorrow, would you have enough cash on hand to survive or is it tied up in inventory? If you lost your main supplier, do you have strong relationships with second and third suppliers who could ensure you aren’t delayed in meeting your customers’ needs?

If you need help determining where you are and how to move closer to antifragile, give me a call.

2 thoughts on “Antifragile Supply Chains: The Next Generation of Productivity”